Improve Wastewater Using Vertical Biofilm Reactors

Imagine a world where the water we need for our crops and livestock is as pure as the crystal streams of yesteryear. Now imagine that we can achieve this purity using a method that is not just effective but also eco-friendly. Enter the vertical biofilm reactor (VBR) for agricultural wastewater treatment—a sustainable technology that promises to revolutionize wastewater treatment and water purification processes. Are you curious about how this advanced wastewater treatment method can transform our approach to ecology of wastewater management? Let’s dive in and explore the fascinating world of vertical biofilm reactors.

The Basics of Vertical Biofilm Reactors

Vertical biofilm reactors represent a cutting-edge approach to water purification processes by harnessing the power of biological filtration. Think of it as the natural way bacteria and microbes work together to clean up waste. These reactors use a medium filled with microorganisms that form a thin film of biofilm on surfaces. This biofilm acts as a filter, breaking down organic pollutants and converting them into harmless substances. The process is akin to a highly efficient, self-cleaning sponge that continually purifies wastewater.

How Vertical Biofilm Reactors Work

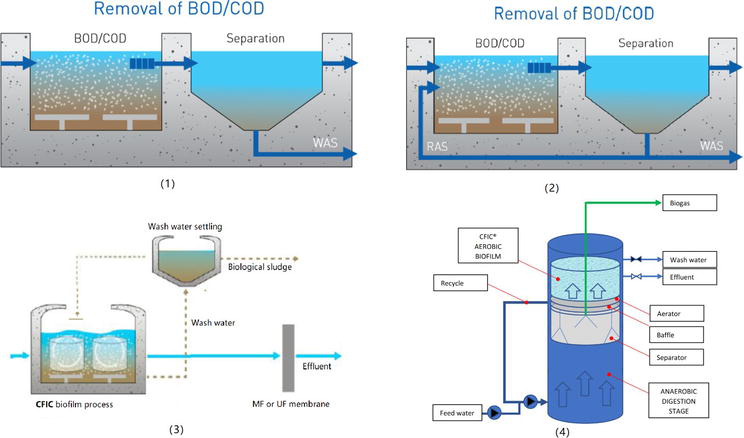

In essence, a vertical biofilm reactor for agricultural wastewater treatment mimics the natural ecological processes found in rivers and wetlands. The reactor itself is often a vertical tank filled with inert material, such as plastic rings or gravel. As wastewater flows through this material, microorganisms attach themselves to the surfaces, forming a biofilm layer. This biofilm layer then degrades the organic pollutants present in the wastewater, converting them into simpler, non-toxic substances.

But how efficient is this biological filtration process? Research has shown that vertical biofilm reactors can significantly reduce levels of chemical oxygen demand (COD), biological oxygen demand (BOD), and suspended solids. Moreover, the vertical orientation of the reactor ensures optimal contact between the wastewater and the biofilm, leading to enhanced treatment efficiency. This means cleaner water, faster, and with less energy consumption compared to traditional water purification processes.

The Ecology of Wastewater Treatment

Understanding the ecology of wastewater is crucial for maximizing the benefits of vertical biofilm reactors. When we talk about the ecology of wastewater, we’re referring to the natural interactions between microorganisms and pollutants. These interactions are what allow vertical biofilm reactors to be so effective. By providing an environment where beneficial bacteria can thrive, we create a self-sustaining system that continuously purifies wastewater.

Imagine your garden. If you tend to it, water it, and provide the right conditions, it flourishes. The same goes for vertical biofilm reactors. When we give these reactors the right conditions—proper aeration, temperature, and nutrient levels—they thrive and purify wastewater efficiently. This is not just sustainable technology; it’s smart technology that learns from nature.

The Role of Biological Filtration

Biological filtration is the cornerstone of vertical biofilm reactors. Unlike chemical treatment methods that rely on harsh agents to purify water, biological filtration uses living organisms to do the job. This approach is not only gentler on the environment but also more cost-effective in the long run. Think of it as outsourcing the hard work to nature’s experts—microorganisms that have been refining their purification skills for millennia.

What makes biological filtration so effective? It’s all about the diversity and adaptability of microorganisms. Different types of bacteria can target different pollutants, breaking them down into harmless components. This is why vertical biofilm reactors are so versatile; they can handle a wide range of contaminants, from organic compounds to heavy metals. And the best part? This process happens naturally, requiring minimal external intervention.

The Advantages of Vertical Biofilm Reactors

Why should you consider vertical biofilm reactors for your wastewater treatment needs? The advantages are manifold, and they extend beyond just clean water. Let’s explore some of the key benefits:

Efficiency and Effectiveness

One of the standout features of vertical biofilm reactors is their efficiency. These reactors can handle high-flow rates and remove pollutants with remarkable effectiveness. Whether you’re dealing with agricultural runoff, industrial discharge, or municipal wastewater, vertical biofilm reactors can provide a robust solution. This makes them an ideal choice for advanced wastewater treatment.

But efficiency isn’t just about processing speed; it’s also about the quality of the output. Vertical biofilm reactors produce water that meets or exceeds regulatory standards, ensuring that the purified water is safe for reuse or discharge into natural water bodies. This means you can have cleaner water without compromising on quality.

Sustainability and Eco-Friendliness

In an era where sustainability is paramount, vertical biofilm reactors stand out as a truly green technology. Unlike traditional methods that rely on chemical treatments, vertical biofilm reactors use biological filtration. This not only reduces the environmental footprint but also cuts down on operational costs. Plus, as a sustainable technology, it aligns with modern ecological practices, promoting a healthier planet for future generations.

But sustainability isn’t just about the process; it’s also about the outcome. Vertical biofilm reactors promote the ecology of wastewater by fostering a diverse microbially robust system. This means that not only do we clean up wastewater, but we also contribute to a healthier ecosystem. It’s a win-win situation for both humans and the environment.

Cost-Effectiveness

One of the biggest concerns with wastewater treatment is the cost. Traditional methods often involve high capital and operating expenses. This is where vertical biofilm reactors shine. By leveraging natural processes, these reactors minimize energy consumption and reduce the need for expensive chemicals. This translates to significant savings over time, making vertical biofilm reactors a cost-effective solution for water purification processes.

But the cost savings don’t stop at operational expenses. Vertical biofilm reactors also reduce the need for frequent maintenance and repairs. Their design and materials ensure longevity, providing reliable performance with minimal downtime. This means you can invest in a wastewater treatment system that delivers long-term value without breaking the bank.

Versatility and Adaptability

Another key advantage of vertical biofilm reactors is their versatility. These reactors can be customized to cater to a variety of wastewater treatment needs. Whether you’re dealing with agricultural runoff, industrial discharge, or municipal wastewater, you can tailor a vertical biofilm reactor to suit your specific requirements. This flexibility makes them an ideal choice for diverse applications.

But versatility isn’t just about adapting to different types of wastewater. It’s also about the adaptability of the ecosystems within the reactor. The biofilm layers can evolve over time to better handle changes in pollutant levels and types. This means that as your wastewater treatment needs change, your vertical biofilm reactor can adapt, providing continuous and effective treatment.

Real-World Applications of Vertical Biofilm Reactors

So, how are vertical biofilm reactors being used in the real world? The applications are vast and varied. From agriculture to industrial settings, these reactors are proving their worth in diverse fields. Let’s explore some real-world scenarios where vertical biofilm reactors are making a difference:

Agricultural Wastewater Treatment

In agriculture, wastewater treatment is a necessity to prevent pollution of water bodies and ensure the health of soil and crops. Vertical biofilm reactors offer an effective solution for treating agricultural runoff, which often contains pesticides, fertilizers, and animal waste. By using these reactors, farmers can purify wastewater and reuse it for irrigation, promoting sustainable farming practices.

But the benefits don’t stop at water quality. The eco-friendly nature of vertical biofilm reactors also promotes a healthier ecosystem. By reducing pollutants in agricultural wastewater, we protect both our land and water resources, ensuring a sustainable future for agriculture. In fact, vertical biofilm reactors that are being used for agricultural wastewater treatment are achieving remarkable results, demonstrating their ability to meet the unique challenges of this sector.

Industrial Wastewater Treatment

Industrial processes generate a significant amount of wastewater that contains various pollutants. From heavy metals to organic compounds, industrial wastewater can be challenging to treat. This is where vertical biofilm reactors come into play. Their ability to handle diverse pollutants makes them an ideal solution for industrial wastewater treatment. By using these reactors, industries can achieve compliance with environmental regulations and reduce their ecological footprint.

But it’s not just about compliance. The use of vertical biofilm reactors can also lead to significant cost savings. By minimizing the need for expensive chemical treatments and reducing energy consumption, industries can lower their operating costs. Plus, the versatility of these reactors means they can be adapted to handle different types of industrial wastewater, ensuring effective treatment across diverse applications.

Conclusions and Future Directions

As we’ve seen, vertical biofilm reactors offer a powerful and sustainable solution for wastewater treatment. Their efficiency, eco-friendliness, and cost-effectiveness make them an ideal choice for advanced wastewater treatment. Whether you’re dealing with agricultural runoff, industrial discharge, or municipal wastewater, vertical biofilm reactors can provide effective and reliable treatment. But the real beauty of these reactors lies in their ability to promote a healthier ecology of wastewater. By harnessing the power of biological filtration, we can purify our water while fostering a diverse and robust microbial ecosystem.

So, let’s embrace this sustainable technology and take the first step towards cleaner, greener water. Explore the possibilities of vertical biofilm reactors for your wastewater treatment needs and discover how they can make a difference in your environment. Click to learn more about this exciting technology and join the movement towards a more sustainable future. Together, we can achieve cleaner water and a healthier planet.

Frequently Asked Questions (FAQs)

Q: What is a vertical biofilm reactor?

A: A vertical biofilm reactor is an advanced wastewater treatment system that uses biological filtration to purify water. It consists of a vertical tank filled with inert material where microorganisms attach to form a biofilm layer that degrades pollutants present in the wastewater.

Q: How effective is vertical biofilm reactor for agricultural wastewater treatment?

A: Vertical biofilm reactors are highly effective for agricultural wastewater treatment. They can significantly reduce levels of COD, BOD, and suspended solids, making the water safe for reuse or discharge into natural water bodies.

Q: Are vertical biofilm reactors eco-friendly?

A: Yes, vertical biofilm reactors are eco-friendly. They use natural biological processes to purify water, thereby reducing the need for harsh chemicals and minimizing the environmental footprint.

Q: Can vertical biofilm reactors be customized for different types of wastewater?

A: Absolutely, vertical biofilm reactors are highly versatile and can be customized to cater to a variety of wastewater treatment needs, including agricultural runoff, industrial discharge, and municipal wastewater.

Q: How do vertical biofilm reactors contribute to sustainable technology?

A: Vertical biofilm reactors contribute to sustainable technology by using natural biological processes to purify water, reducing energy consumption, and promoting a robust microbial ecosystem. This makes them an eco-friendly and cost-effective solution for water purification processes.

0 Response to " Improve Wastewater Using Vertical Biofilm Reactors"

Post a Comment